Products

Customized & profitable automation solutions

Crate Stacking

Crate Testing

Packaging Destacker

Pallet Turner

Pallet Stacker

Conveyor System

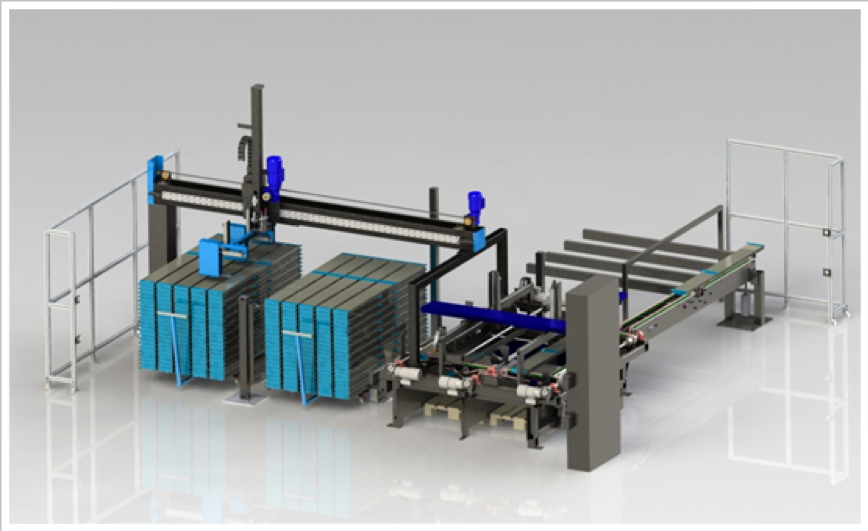

Crate Stacking

Crate Testing

Rational and ergonomic handling of crates.

Stacks and tests 500 crates per hour.

The Crate comes from an assembly line or is manually placed on to the Crate conveyor. The Crate goes into the line, then the crate turns so that the crate hinges ends up correct on the pallet, according to the stacking pattern chosen by the customer. The Crate Stacker then lifts up the crate from the Crate conveyor and stacks it onto the pallet. When the first bundle is full, the stacker continues to the other bundle. The machine has two test stations which tests the crates four hinges.

Safety regulations (CE)

The machine is provided with all types of security measures required by the present machine directive (EU). The machine is CE marked.

Safety regulations (CE)

The machine is provided with all types of security measures required by the present machine directive (EU). The machine is CE marked.

Capacity

The machine manages to test the hinges of the crate and stack at least one crate every 7:th second.

Staff required

One operator (depending on the volume).

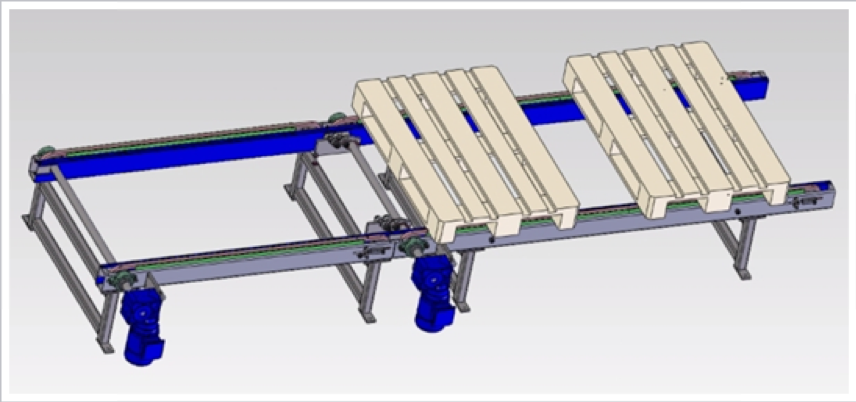

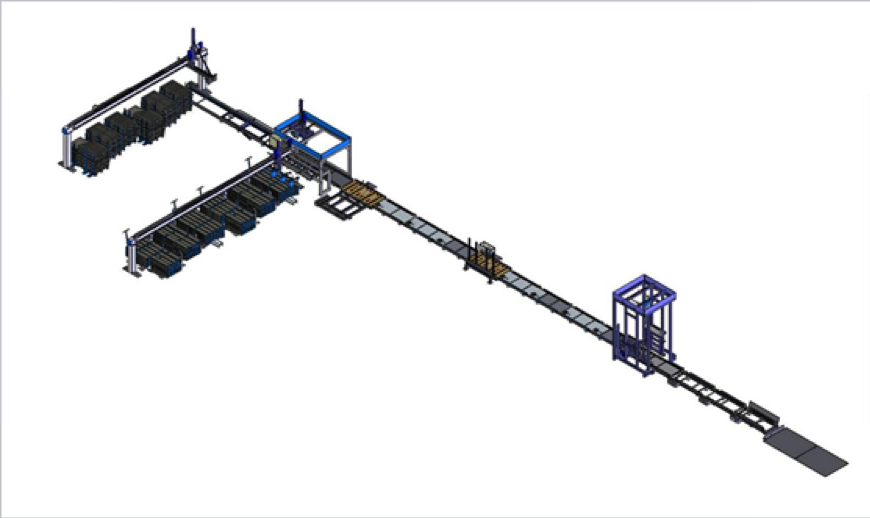

Conveyor system

We design pallet lines so they fit your facility. We also integrate the system according to your demands and needs.

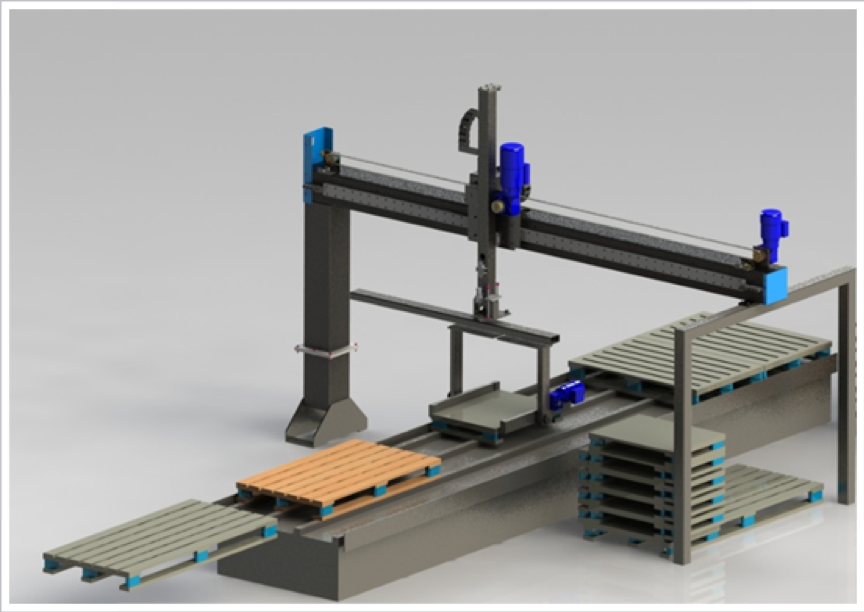

Pallet Turner

Pallet Stacker

Ergonomic handling of pallets/pallet bundles. Flexible Destacker/Stacker that manages to disassemble crossed pallet bundles.

The Pallet turner manages to disassemble crossed pallet bundles and then place them on the floor or onto a transport conveyor . It is also possible to stack the pallets straight up or cross the bundles.

Safety regulations (CE)

The machine is provided with all types of security required by the present machine directive (EU). The machine is CE marked.

Staff required

One operator (depending on the volume).

Packaging Destacker

Rational and ergonomic handling of crates and pallets. An automated machine for Destacking of packaging with high speed.

The Destacker has a function similar to a fully automatic (standstill) fork truck. The forks with axis form goes in and out. The whole fork carriage goes up and down. To detect where the forks should go in, we use double laser photocells. All sensors and cables are well protected. The Destacker has a lifting capacity of 300 kilos. It has a capacity of: 1 box/15 second (at a height of 3 crates).